Concrete is an unsung hero in the world of construction. From the sturdy base of your home to the smooth pathways you walk on, it's everywhere. This versatile material forms the backbone of countless structures we interact with daily. Understanding its different uses isn't just for builders; it's valuable for anyone involved in a construction project.

Concrete work isn't a one-size-fits-all solution; it's a specialized craft. Its applications vary widely depending on the project's needs. Whether you're a homeowner planning a new patio, a property manager overseeing repairs, or a general contractor building a commercial space, knowing the types of concrete work helps you make informed decisions. It ensures the right material and methods are used for lasting results.

This article will break down the three main types of concrete work: foundational concrete, concrete flatwork, and structural concrete. We'll explore what each type involves, why it's important, and what goes into making it happen. By the end, you'll have a clear picture of concrete's diverse roles in construction.

Foundational Concrete Work

Imagine a house without a strong base; it simply wouldn't stand. That's where foundational concrete work comes in. It's all about creating the sturdy support system that transfers the weight of a building safely to the ground.

This type of concrete is arguably the most critical part of any construction project, as it directly impacts the stability and longevity of the entire structure. A well-built foundation prevents settling, cracking, and even structural failure over time. It's the silent workhorse that keeps your building upright and secure.

There are several common types of concrete foundations, each suited for different soil conditions, climates, and building designs. The three most prevalent are slab-on-grade, crawlspace, and basement foundations.

Each method uses concrete in a specific way to provide the necessary support and protection for the building above. Understanding these types is key to appreciating the complexity and importance of foundational concrete.

Slab-on-Grade Foundations

A slab-on-grade foundation is essentially a single, thick layer of concrete poured directly on the ground. It's popular in areas with mild climates where frost heave (the upward movement of soil caused by ice forming below the surface) isn't a major concern.

The slab often includes thickened edges or "footings" that extend deeper into the ground to provide extra support for the building's walls. Before pouring, a layer of gravel is typically laid down, followed by a vapor barrier to prevent moisture from rising through the concrete.

The process begins with preparing the site, which involves clearing and leveling the ground. Trenches are then dug for the footings, and a formwork (a temporary mold) is built to hold the concrete in place.

Reinforcement, such as rebar (steel reinforcing bars) or wire mesh, is laid out within the formwork to add strength and prevent cracking.

Finally, the concrete is poured, leveled, and allowed to cure, gaining its full strength over time. The simplicity and cost-effectiveness of slab-on-grade foundations make them a common choice for many residential and light commercial buildings.

Crawlspace Foundations

Crawlspace foundations lift the building slightly off the ground, creating a shallow space underneath. This space, usually between 2 to 4 feet high, allows access for plumbing, electrical wiring, and HVAC ducts.

The foundation typically consists of concrete footings that support concrete block or poured concrete walls, which in turn support the main floor structure of the building. This design helps protect the house from ground moisture and allows for easier maintenance and repairs of under-house systems.

Building a crawlspace involves digging trenches for the footings first. Once the footings are poured and cured, a series of concrete block walls or poured concrete walls are constructed on top of them. These walls create the perimeter of the crawlspace and provide the support for the floor joists.

A vapor barrier is often laid on the ground within the crawlspace to manage moisture, and vents are installed in the foundation walls to allow for air circulation. While more complex than a slab-on-grade, crawlspaces offer significant advantages in terms of accessibility and moisture control.

Basement Foundations

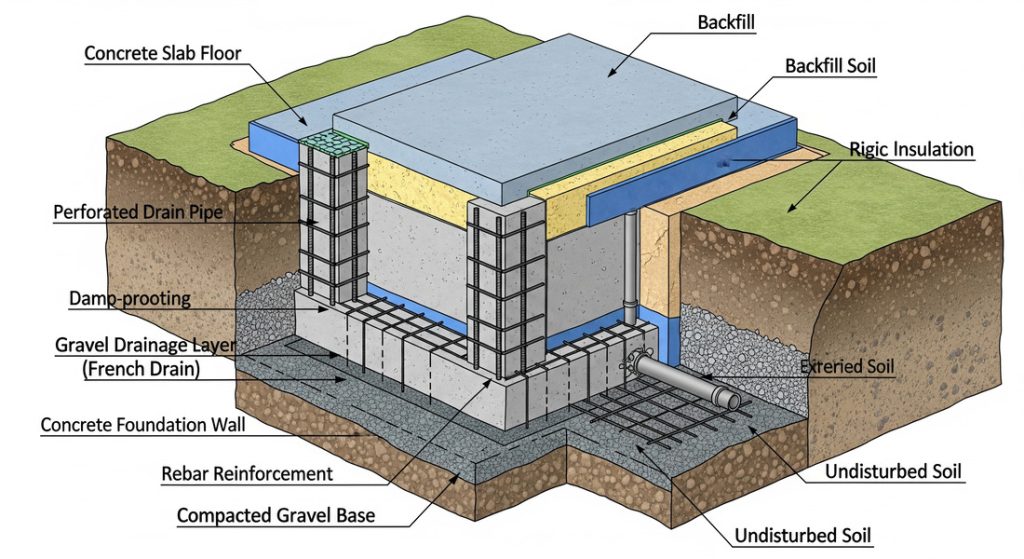

Basement foundations create a full-height living or storage space below ground level. These are common in colder climates where foundations need to extend below the frost line to prevent damage from freezing and thawing soil.

A basement provides significant extra square footage for a home, often used for additional bedrooms, recreation rooms, or utilities. The concrete walls of a basement bear the weight of the entire structure above and also resist the lateral pressure from the surrounding soil.

The construction of a basement involves extensive excavation to the desired depth. Concrete footings are then poured at the base of the excavation, followed by the erection of tall formwork for the basement walls.

Rebar is strategically placed within the forms to reinforce the concrete and give it tensile strength. Once the concrete is poured and cured, it forms robust walls capable of supporting the entire house.

Waterproofing membranes and drainage systems are crucial components of basement construction to prevent water intrusion. The complexity and material requirements make basements more expensive, but the added usable space often justifies the investment.

The Process, Materials, and Challenges

The process of laying a concrete foundation is meticulous and requires skilled labor. It typically begins with site preparation, which involves clearing the land, leveling it, and ensuring proper drainage. Next comes excavation, digging to the specified depth for footings or basements. Formwork is then built, creating the mold for the concrete.

This must be accurately constructed and braced to withstand the immense pressure of wet concrete. Reinforcement, primarily rebar, is then carefully placed within the forms, tied together to create a strong mesh. The concrete pour is a critical step, requiring proper mixing, delivery, and placement.

After pouring, the concrete undergoes curing, a process where it hardens and gains strength. This involves keeping the concrete moist for a period, which allows it to reach its full potential strength and prevents cracking. Inspections are conducted at various stages to ensure compliance with building codes and engineering specifications.

Common materials used include Portland cement, aggregates (sand, gravel), water, and admixtures (chemicals that modify concrete properties).

Challenges can include unpredictable soil conditions, adverse weather, and the need for precise measurements and levels. Ensuring a level and strong foundation is paramount for the safety and longevity of any building.

Benefits of a Solid Concrete Foundation

A solid concrete foundation offers a multitude of benefits that are crucial for any structure. First and foremost, it provides structural integrity, ensuring the building remains stable and secure for decades. This prevents issues like uneven settling, which can lead to cracks in walls and floors, doors and windows sticking, and even more serious structural damage. A well-built foundation acts as a stable anchor, resisting the forces of nature like wind and seismic activity.

Beyond stability, concrete foundations offer excellent durability and longevity. They are resistant to rot, pests, and fire, unlike some other foundation materials. This inherent toughness means they require minimal maintenance over their lifespan, saving homeowners and property managers significant costs in the long run.

Furthermore, concrete foundations contribute to the energy efficiency of a building by providing a thermal mass that helps regulate indoor temperatures. In the case of basements, they offer valuable extra space that can be used for living, storage, or utilities, adding significant value to the property. Investing in a high-quality concrete foundation is an investment in the long-term health and value of any building.

Concrete Flatwork

When you think of concrete surfaces you walk or drive on, you're likely thinking of concrete flatwork. This type of concrete work refers to any horizontal concrete surface that is relatively thin and wide. It's about creating durable, functional, and often aesthetically pleasing surfaces for everyday use.

From the path leading to your front door to the vast expanse of a commercial parking lot, flatwork is integral to both the utility and appearance of a property. It's the concrete you interact with most frequently, making its proper installation and maintenance crucial.

Common examples of concrete flatwork include driveways, patios, sidewalks, garage floors, and pool decks. Each of these applications requires specific considerations regarding thickness, reinforcement, and finish to ensure it performs its intended function

effectively and looks good doing it. The goal of concrete flatwork is to provide a smooth, stable, and long-lasting surface that can withstand foot traffic, vehicle loads, and varying weather conditions. Good flatwork enhances curb appeal and increases property value.

Step-by-Step Explanation of How Flatwork is Installed

Installing concrete flatwork takes careful planning and precision. It starts with clearing and grading the site, then compacting the base to prevent future cracks or settling.

Formwork is set to define shape and thickness, followed by reinforcement with rebar or wire mesh for added strength. Control and expansion joints are added to manage movement and minimise cracking.

Once everything is ready, concrete is poured, screeded, and floated to create a level, smooth surface, preparing it for the final finish.

Ready to lay a solid foundation? Contact us today for professional flatwork done right from the ground up.

Finishes for Concrete Flatwork

One of the most appealing aspects of concrete flatwork is the variety of finishes that can be applied, allowing for customization and enhanced aesthetics. Beyond a simple smooth surface, different techniques can transform the look and feel of the concrete.

The choice of finish often depends on the desired appearance, the function of the surface, and the budget. Each finish offers unique benefits in terms of slip resistance, durability, and visual appeal. Some of the main finishes include:

Broom finish

This is one of the most common and practical finishes. After the concrete is poured and floated, a special broom is dragged across the surface, creating fine lines. This texture provides excellent slip resistance, making it ideal for sidewalks, driveways, and pool decks where safety is a concern. It's a simple, cost-effective, and very durable option.

Stamped concrete

The finish offers a decorative touch, mimicking the appearance of more expensive materials like brick, flagstone, slate, or wood. Specialized mats with various patterns are pressed into the wet concrete, creating realistic textures and designs.

This technique can dramatically enhance the curb appeal of patios, walkways, and driveways, providing a high-end look without the high cost and maintenance of natural stone. It's an excellent way to add character and unique style.

Colored concrete

Comored concrete is achieved by adding pigments directly to the concrete mix or by applying a color hardener to the surface. This allows for a wide range of hues, from subtle earth tones to vibrant shades, complementing the surrounding architecture or landscape. Colored concrete can be combined with stamping or other finishes to create truly custom designs. It's a durable way to add visual interest.

Other finishes include exposed aggregate, where the top layer of concrete is washed away to reveal the decorative stones or pebbles within the mix, creating a textured and often visually appealing surface.

Polished concrete provides a smooth, high-gloss finish, often used for interior floors in commercial or modern residential settings. The choice of finish can greatly impact the overall appearance and functionality of the concrete surface.

Tools, Techniques, and How It Adds Curb Appeal and Functionality

Successful concrete flatwork installation relies on a combination of specialized tools and practiced techniques. Beyond the basics like shovels and wheelbarrows, concrete contractors use a variety of equipment for different stages of the process.

Screeds are used to level the concrete, ensuring a uniform thickness. Floats (hand, bull, and power floats) smooth the surface and bring "cream" to the top.

Trowels (hand trowels, power trowels) are used for final smoothing and compaction. Specialized brooms, stamping mats, and coloring tools are used for decorative finishes.

The techniques involved are equally important. Proper mix design ensures the concrete has the right strength and workability.

Correct placement and consolidation prevent air pockets and ensure a dense, strong slab. Curing is critical; protecting the concrete from rapid drying allows it to gain maximum strength and minimizes cracking. Understanding factors like temperature, humidity, and proper joint placement is crucial for a long-lasting and aesthetically pleasing result.

Concrete flatwork significantly enhances both the curb appeal and functionality of any property. A well-designed and installed driveway provides a durable and attractive approach to a home, making a strong first impression. Patios and pool decks create inviting outdoor living spaces, perfect for entertaining or relaxation.

Sidewalks offer safe and accessible pathways. The ability to customize flatwork with various finishes and colors means it can complement any architectural style, from traditional to modern.

Beyond aesthetics, concrete's inherent strength and low maintenance contribute significantly to the practical usability of these areas. It provides a solid, level surface that can withstand heavy use and various weather conditions, increasing the overall utility and value of the property.

Maintenance and Longevity

Concrete is tough, but it still needs regular care to stay strong and look its best. Simple routines like cleaning, sealing, and repairing cracks can greatly extend its life and prevent costly damage.

Sweep away debris, clean spills quickly, and pressure wash with care. Apply a quality sealer every few years to protect against moisture, stains, and weather. Fix cracks early to stop them from spreading.

Protect your investment. Get expert advice or schedule maintenance with us today.

Structural Concrete Work

When we talk about structural concrete work, we're referring to concrete that is specifically designed to bear significant weight or resist substantial forces.

Unlike flatwork, which primarily provides a surface, structural concrete forms the load-bearing elements of buildings, bridges, and other large structures. Its primary role is to provide strength, stability, and rigidity, ensuring the entire structure can stand safely and withstand the stresses it will encounter over its lifetime. This type of concrete is engineered with precision to meet stringent safety and performance standards.

The applications of structural concrete are vast and critical to modern infrastructure. You'll find it in the towering columns of high-rise buildings, the expansive decks of bridges, and the robust walls of parking garages. It's the skeleton that holds everything together.

Because of its crucial role, structural concrete work requires meticulous planning, precise execution, and a deep understanding of engineering principles. The failure of structural concrete can have catastrophic consequences, emphasizing the importance of expert workmanship.

Key Applications of Structural Concrete

Structural concrete is foundational to many of the largest and most complex constructions in our modern world. Its strength, durability, and ability to be molded into various shapes make it indispensable for structures that must withstand immense loads and stresses. These applications often define our urban landscapes and critical transportation networks. Understanding these uses highlights the versatility and importance of structural concrete in civil engineering.

Bridges

Bridges are prime examples of structural concrete applications. Whether it's the towering piers supporting a highway overpass or the reinforced decks of a major river crossing, concrete provides the necessary strength to carry heavy vehicle traffic and resist environmental forces. Concrete bridges are known for their longevity and low maintenance compared to other materials. The material's compressive strength makes it ideal for supporting heavy loads.

Parking Structures

These structures rely heavily on structural concrete. Multi-story parking garages utilize concrete columns, beams, and slabs to create a robust framework capable of supporting thousands of tons of vehicles. The concrete must be designed to withstand constant vibration, heavy loads, and exposure to vehicle fluids and road salts. Precast concrete elements are often used in these structures for faster construction and consistent quality.

Multi-story Buildings

From residential apartment complexes to towering office skyscrapers, are constructed with structural concrete frames. Concrete columns and beams form the skeleton of the building, supporting the weight of floors, walls, and occupants. Reinforced concrete shear walls are often incorporated to resist lateral forces from wind and earthquakes, ensuring the building's stability. The ability to pour concrete into virtually any shape allows for architectural flexibility.

Other key applications include dams, where massive concrete structures hold back vast amounts of water; tunnels, where concrete provides strong linings; and foundations for large machinery, where precision and immense strength are required.

Structural concrete is also integral to retaining walls that hold back soil on steep slopes and underground utility vaults that protect critical infrastructure. In each of these applications, the engineering of the concrete mix, the placement of reinforcement, and the quality of the pour are paramount for safety and longevity.

Explaining Rebar, Formwork, Curing, and Inspections Simply

The success of structural concrete work hinges on several fundamental components and processes that ensure its strength and durability. These elements work together to create a robust and reliable structure. Understanding them simply can demystify the complex world of structural concrete. Each step is critical to the final outcome.

Rebar

Rebar, short for reinforcing bar, is essentially steel rods or mesh embedded within the concrete. Concrete is incredibly strong when compressed (pushed together) but relatively weak when pulled apart (in tension).

Steel, on the other hand, is excellent at resisting tension. By combining rebar with concrete, you create reinforced concrete, a material that leverages the best properties of both. The rebar gives the concrete the tensile strength it needs to resist bending and cracking under load, ensuring the structure's overall stability. It’s the invisible skeleton inside the concrete.

Formwork

This refers to the temporary molds or structures into which wet concrete is poured. Think of it as a giant, custom-built container that holds the concrete in its desired shape until it hardens and gains enough strength to support itself.

Depending on the scale and complexity of the project, formwork can be made from wood, steel, aluminum, or plastic. It must be strong enough to withstand the immense pressure of the wet concrete and precisely built to achieve the exact dimensions and alignment required by the structural design. Once the concrete cures, the formwork is typically removed.

Curing

Curing is maintaining adequate moisture and temperature in concrete after it has been poured to allow it to harden and gain its maximum strength. Concrete doesn't just "dry out" to get strong; it undergoes a chemical reaction called hydration.

This reaction needs water to complete. If concrete dries out too quickly, it can lead to weaker concrete and surface cracking. Curing can involve spraying water on the concrete, covering it with wet burlap, applying curing compounds, or even ponding water on the surface. Proper curing is essential for structural concrete's long-term strength, durability, and crack resistance.

Inspections

These are a series of checks performed throughout the structural concrete process to ensure quality and compliance with design specifications and building codes. Qualified engineers and inspectors carry these out.

Inspections typically occur at various stages: before the rebar is placed to check its size and spacing, after the formwork is built to verify its dimensions and stability, during the concrete pour to ensure proper mix and placement, and after curing to confirm strength and finish. These rigorous inspections are vital for guaranteeing the safety and integrity of the structural concrete elements, ensuring they will perform as intended for decades.

Highlighting Safety, Engineering, and Common Materials

Safety

Safety is paramount in all concrete work, especially in structural concrete applications. These projects' sheer scale and load-bearing nature mean that even minor errors can have catastrophic consequences.

Strict safety protocols are implemented on job sites, including proper use of personal protective equipment (PPE), safe handling of heavy machinery, and secure erection of formwork and scaffolding. Workers must be trained to recognize and mitigate hazards. Regular safety briefings and adherence to industry regulations are non-negotiable to protect lives and prevent accidents.

Engineering

This is the backbone of structural concrete work. Every structural concrete element, from a single column to an entire bridge deck, is meticulously designed by structural engineers. They use complex calculations to determine the exact size, shape, and reinforcement required to support anticipated loads and forces safely.

Engineering involves understanding material properties, soil conditions, environmental factors (like wind and seismic activity), and building codes. The engineer's blueprints guide the entire construction process, ensuring that the concrete performs its critical role reliably and safely for its intended lifespan. Without sound engineering, structural concrete would simply be a pile of material.

Common Materials

Common materials for structural concrete are similar to those for other concrete types, but often with more stringent specifications. Portland cement acts as the binder, reacting with water to form the paste that holds everything together. Aggregates (sand, gravel, crushed stone) provide bulk and strength.

Water is crucial for the chemical reaction and workability. However, the water-to-cement ratio is often carefully controlled for structural concrete to achieve specific strength requirements. Admixtures are frequently used to modify concrete properties, such as increasing workability, accelerating or retarding setting times, or enhancing durability.

Crucially, steel rebar is almost always a component, providing the necessary tensile strength that plain concrete lacks. The quality and proportions of these materials are rigorously tested and monitored to meet the high demands of structural applications.

Comparison of Types

Understanding the differences between foundational, flatwork, and structural concrete is essential for appreciating their distinct roles in construction. While all involve concrete, their purpose, complexity, required equipment, and expertise vary significantly. This comparison highlights why each type demands specific approaches and considerations. Recognizing these distinctions helps in planning projects and selecting the right professionals for the job.

| Feature | Foundational Concrete Work | Concrete Flatwork | Structural Concrete Work |

| Primary Use | Supports entire building; transfers load to ground. | Creates horizontal surfaces for walking/driving; enhances usability. | Forms load-bearing elements (columns, beams, slabs) for large structures. |

| Complexity | High (critical for stability, involves excavation, waterproofing). | Moderate (surface preparation, leveling, finishing, aesthetic options). | Very High (requires detailed engineering, precise formwork, high strength). |

| Equipment | Excavators, large concrete pumps, vibrators, surveying tools. | Concrete trucks, screeds, floats, trowels, power tools for finishing. | Cranes, heavy-duty pumps, specialized formwork systems, testing equipment. |

| Expertise | Geotechnical knowledge, structural engineering, experienced pour crews. | Skilled finishers, understanding of drainage and aesthetic techniques. | Advanced structural engineering, certified welding (for rebar), rigorous quality control. |

| Reinforcement | Essential (rebar, mesh) to prevent settling and cracking. | Common (rebar, wire mesh) for durability and crack control. | Absolutely Critical (extensive rebar, post-tensioning) for load bearing. |

| Typical Location | Below ground, perimeter of buildings. | Ground level (driveways, patios), garage floors. | Throughout the building's frame, bridges, parking garages. |

How to Choose the Right Concrete Contractor

Choosing the right concrete contractor is one of the most critical decisions for any concrete project. Whether you're a homeowner planning a new driveway or a general contractor seeking a partner for a major build, the quality of workmanship directly impacts the longevity, safety, and appearance of the concrete.

A poor choice can lead to costly repairs, delays, and significant frustration. Properly vet potential contractors will save you headaches and ensure a successful outcome.

The goal is to find a professional who is experienced, reliable, and committed to high-quality work.

Don't rush into a decision based solely on price. While budget is important, it should be balanced with factors like reputation, expertise, and communication. A cheaper bid could end up costing you more in the long run if the work is subpar. Prioritize value and peace of mind when making your selection.

Practical Tips for Homeowners or Builders Choosing a Contractor

When starting your search, begin by gathering recommendations. Ask friends, family, neighbors, or other local professionals for contractors they've had positive experiences with. Online reviews and ratings can also provide valuable insights, but always cross-reference them once you have a list, schedule consultations to discuss your project in detail. This allows you to assess their professionalism and communication style.

Always request a detailed, written estimate from multiple contractors. This estimate should clearly outline the scope of work, materials to be used (including concrete mix design and any reinforcement), project timeline, and total cost. Be wary of estimates that are significantly lower or higher than others, and ask for clarification on any discrepancies. A transparent estimate demonstrates professionalism and helps avoid hidden costs later.

What to Ask, Credentials to Look For, and How to Avoid Poor Workmanship

When interviewing potential contractors, ask specific questions to gauge their expertise and reliability. Inquire about their experience with similar projects to yours.

For example, if you need a basement foundation, ask about their history with complex excavations and waterproofing. Ask about their team's qualifications and whether they use their crews or subcontractors. Contractors who use their experienced crew often offer consistent quality control.

Crucially, check their credentials. Ensure the contractor is licensed and insured. A license indicates they meet state or local requirements, while insurance (liability and worker's compensation) protects you from financial responsibility in case of accidents or damage on your property.

Ask for proof of both and verify them. Request references from previous clients and take the time to call them. Ask references about the contractor's punctuality, adherence to budget, communication, and overall satisfaction with the finished product. Look for signs of good project management and problem-solving skills.

Pay attention to how the contractor communicates and organizes their information to avoid poor workmanship. A professional contractor will be organized, provide clear answers, and be willing to explain their process. Avoid anyone who pressures you into a quick decision, demands full payment upfront, or answers your questions vaguely.

A reputable contractor will also be transparent about potential challenges and solutions. Don't hesitate to ask about their quality control measures and how they handle unforeseen issues.

Finally, ensure a comprehensive contract is signed before any work begins. This contract should detail everything from the scope of work and payment schedule to warranties and dispute resolution, protecting both parties.

Conclusion

Concrete, in its many forms, is undeniably the bedrock of our built environment. From the unyielding foundations that support our homes to the smooth surfaces of our driveways and the towering structures that define our cities, its versatility and strength are unmatched.

Understanding the distinct types of concrete work, foundational, flatwork, and structural, demystifies the construction process and highlights the specialized skills required for each. Recognizing each type's critical role ensures that projects are planned and executed with the precision and care they deserve.

Whether you're embarking on a small home improvement or overseeing a large-scale commercial development, the quality of your concrete work directly impacts your investment's safety, durability, and value. It’s not just about mixing and pouring; it’s about engineering, precision, and a deep understanding of the material. When it comes to something as fundamental as concrete, expertise truly matters.

Don’t wait until cracks get worse. Let our experts keep your concrete in top shape. Call now for a quick quote and personalised advice.