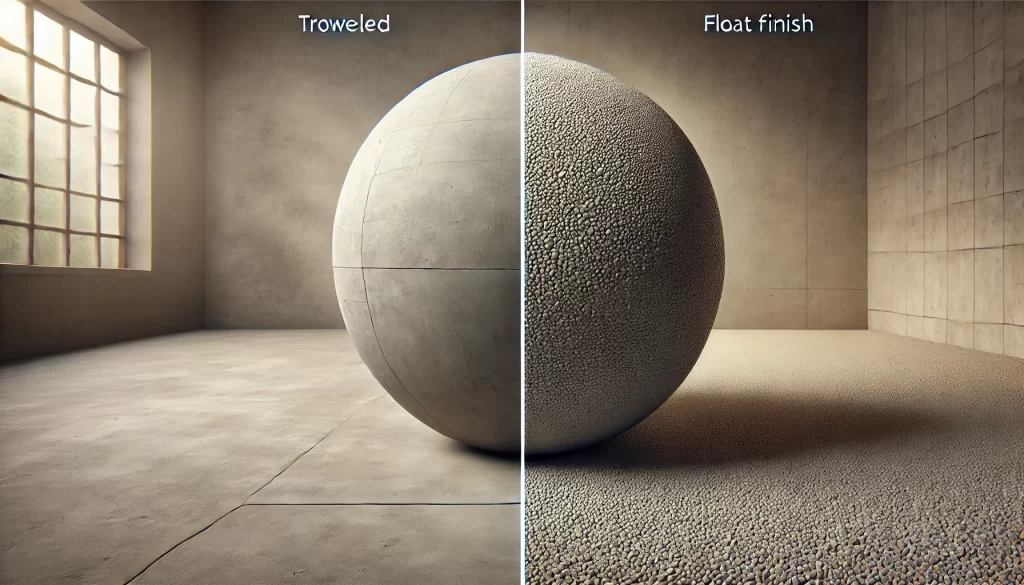

Every concrete slab needs a finish, and the choice often comes down to how smooth, textured, or functional the final surface should be. Two of the most widely used methods are troweled and float finishes. Both serve important roles in shaping the performance and appearance of concrete, but they differ in application, outcome, and long-term use.

Contractors consider both troweling and floating as essential steps in the broader set of concrete finishing techniques. While broom, exposed aggregate, and polished finishes often catch attention for their style or safety benefits, the trowel and float are more about building a strong foundation and achieving the right level of smoothness before a slab goes into service.

Understanding Float Finishes

Floating is one of the first finishing steps performed after concrete is poured and roughly levelled. Using either a hand float or a bull float, contractors smooth out ridges, fill voids, and compact the surface slightly. The goal is not to achieve a glassy surface but to create a uniform, moderately textured slab.

Float finishes often leave a matte, slightly gritty appearance that provides grip and durability. This makes them ideal for surfaces where traction is important or where the slab will later receive another treatment, such as tile, carpet, or epoxy coatings.

Experienced contractors know that the float stage is critical because it sets the base for everything that follows. Done well, it ensures the slab cures evenly and reduces the risk of cracking. Done poorly, it can leave uneven surfaces that compromise both appearance and performance.

Understanding Trowel Finishes

Troweling typically follows floating and refines the surface further. Using hand trowels or power trowels, contractors compress the surface paste to create a dense, smooth finish. With repeated passes, the surface can become highly polished, almost reflective, depending on project requirements.

A trowel finish is valued for its sleek appearance and ease of cleaning. Warehouses, factories, and even residential garages often rely on troweled floors for their durability and low-maintenance qualities. Because the surface is denser, it also resists dusting and moisture absorption better than floated finishes.

Achieving a consistent trowel finish takes skill and timing. Too much pressure too early can weaken the surface, while too little pressure can leave it rough. Seasoned professionals understand how to read the concrete’s set time, weather conditions, and slab size to deliver the right finish.

Key Differences Between Troweled and Float Finishes

Texture

- Float finish leaves a slightly rough, matte surface.

- Trowel finish results in a smooth, dense surface that can be polished further.

Application

- Floating is an initial step, performed soon after pouring.

- Troweling is done later, once the surface has set enough to withstand greater pressure.

Durability

- Float finishes are strong but slightly more porous.

- Trowel finishes are denser, offering greater resistance to wear and staining.

Appearance

- Floated slabs look natural and utilitarian.

- Troweled slabs appear refined and can range from satin to glossy.

Where Float Finishes Work Best

Exterior Pavements

Float finishes are common for outdoor pavements where grip is essential and appearance is secondary. The matte surface ensures safer footing.

Subfloors

Because floated concrete is relatively inexpensive and quick to produce, it’s often used as a subfloor beneath carpets, hardwood, or tiling.

Utility Spaces

Basements, storage areas, and sheds often use float finishes because they’re functional, durable, and affordable.

Where Trowel Finishes Work Best

Industrial Facilities

Warehouses and factories benefit from troweled finishes that resist heavy wear and make cleaning easier.

Garages

A smooth, troweled garage floor provides durability while reducing dust. It also makes oil spills and dirt easier to clean.

Retail and Commercial Spaces

Troweled concrete can be further polished for a professional, high-end appearance, making it ideal for commercial interiors.

Expert Insights on Choosing Between the Two

Contractors often explain the choice between floated and troweled surfaces as a matter of purpose. If the surface is intended as a base for another material, or where grip is critical, floating makes sense. If the slab is meant to stand on its own and needs to be easy to clean, troweling is the better choice.

It’s also important to consider environment. Outdoor paths and pavements benefit from float finishes because they provide traction, while indoor industrial spaces favour trowel finishes for their density and low dusting.

Professionals also emphasise the importance of experience. These techniques may look simple, but getting the timing and pressure right requires years of practice. Poorly floated or troweled slabs can lead to premature cracking, surface dusting, or unevenness.

Maintenance Considerations

Float Finishes

Floated surfaces are generally low-maintenance but may require sealing to protect against moisture or staining. Because they are slightly more porous, they can accumulate dust if left untreated.

Trowel Finishes

Troweled surfaces are denser and easier to maintain. Regular sweeping and occasional washing are usually sufficient. Sealing enhances stain resistance and longevity.

Potential Drawbacks

- Float finishes can appear basic or rough, making them less desirable for decorative spaces. They may also need more frequent sealing in moisture-prone areas.

- Trowel finishes can be slippery if not treated with anti-slip coatings. Over-troweling may also cause surface scaling or cracking.

Combining Float and Trowel Approaches

In practice, floating and troweling are not mutually exclusive. Many slabs receive both treatments in sequence — floating to level and prepare the surface, followed by troweling to densify and refine it. This layered approach ensures the slab is both structurally sound and visually appealing.

Contractors often describe this as “working with the concrete as it sets.” Floating addresses early imperfections, while troweling locks in long-term durability.

Design Options

While both finishes are primarily functional, there is still some room for creativity. Contractors can adjust the type of float or trowel, the angle of application, and the number of passes to achieve different effects. For example, a light trowel pass leaves a matte finish, while multiple passes create a polished sheen.

Floated surfaces can also be used as bases for overlays or coatings, allowing designers to build on a reliable foundation.

Why These Finishes Still Matter Today

Despite the rise of decorative techniques like stamping or polishing, float and trowel finishes remain essential in modern construction. They’re practical, cost-effective, and form the backbone of countless projects. Contractors continue to rely on them because they balance efficiency with long-term performance.

For property owners, choosing between the two comes down to intended use. Float finishes deliver grip and affordability, while trowel finishes provide sleekness and strength. Both represent time-tested methods that continue to meet the demands of today’s construction industry.

Conclusion

Troweled and float finishes are often compared side by side, but they really serve complementary roles. Floating provides the groundwork — levelling and preparing the slab — while troweling refines and strengthens the surface. Each method has distinct advantages depending on whether the priority is traction, durability, or appearance.

These two approaches stand out not for decoration but for their practicality. They are the unsung heroes of concrete work, shaping surfaces that last decades and providing the foundation for both functional and decorative projects.